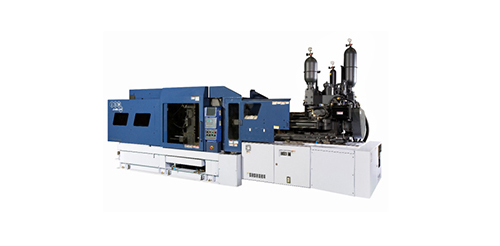

Prosper (Hong Kong) Co., Ltd. specializes in Japan JSW Nippon Steel injection molding machine, integrated import injection molding equipment sales service-oriented enterprise.

4News -> FAQ

What are some points about the unloading design of the injection molding machine manipulator? The injection molding machine manipulator is a machine specially equipped for injection molding production automation equipment. It uses different mechanisms for fast and effective loading and unloading operations for different injection molded products. The special unloading manipulator for injection molding machines is one of them.

The special manipulator unloading machine for the injection molding machine consists of two parts: a take-out plate and a discharge plate. There are troughs on the take-out plate and the unloading plate for placing preforms. There is an air pipe at the back of the trough for blowing or vacuum suction operation. The take-out plate can move left and right along the guide rail, and the discharge plate can be moved back and forth by the hydraulic cylinder, and can be rotated by 90° by the hydraulic swing cylinder.

The working process of the manipulator of the injection molding machine: firstly, the injection molding machine partly completes the injection and gets a mold opening signal. The board is taken out and enters at this time. After the board is taken out in place, there will be a thimble in the template part of the injection molding machine to eject the preform. Then the vacuum valve of the take-out plate is opened, and the preform is sucked from the mold onto the take-out plate. After all the preforms have been reprinted, the electric eye test confirms that all the preforms are on the take-out board, and the retracting action begins. After returning to the position, the unloader starts to advance to the unloading position, and the unloading plate is attached to the unloading plate.

The ejection plate vacuum of the manipulator of the injection molding machine is released and the air is blown. The vacuum on the unloading hand is opened, and all the materials are loaded on the unloading hand. At this time, the unloader returns to its original position and reverses in the original position, from the vertical position to the horizontal position, the unloader's vacuum is released, the preform falls on the conveyor belt installed at the bottom, and the unloading is completed. The unloading hand is then reversed from the horizontal position to the vertical position.

This manipulator control system uses PLC as the control core, which makes the system highly reliable, easy to maintain, strong in scalability, and easy to use. The fixed group and compensation group are composed of one lens, the zoom group is composed of two lenses, and the rear fixed group is composed of three lenses. Lens composition.

The front fixed group is used to focus close objects; the zoom group changes the focal length of the system by moving; the compensation group keeps the image plane stable by cam movement; the rear fixed group is used to assume most of the optical power of the system, because the zoom system compensates The group's optical power is negative, so the system is a negative group compensation system.

The injection molding machine manipulator, which is based on air pressure, hydraulic transmission and PLC control technology, works reliably and is easy to integrate with the injection molding machine, which greatly improves the production efficiency of the injection molding machine.